Selecting the right frozen seafood suppliers is a critical decision that can significantly impact your business operations, product quality, and customer satisfaction. International buyers face unique challenges when sourcing from global suppliers, including quality assurance, regulatory compliance, logistics coordination, and maintaining consistent supply chains. Understanding the key factors that distinguish reliable suppliers from unreliable ones enables businesses to make informed decisions that protect their investments and ensure long-term success in the competitive seafood market.

Essential Criteria for Evaluating Supplier Qualifications

Certification and Compliance Standards

Reputable frozen seafood suppliers must possess comprehensive certifications that demonstrate their commitment to food safety and quality management. International buyers should prioritize suppliers holding HACCP (Hazard Analysis Critical Control Points) certification, which ensures systematic food safety management throughout the production process. Additionally, ISO 22000 certification indicates that suppliers have implemented robust food safety management systems that meet international standards.

Beyond basic food safety certifications, suppliers should maintain specific seafood industry certifications such as BAP (Best Aquaculture Practices) or MSC (Marine Stewardship Council) certification for sustainable sourcing practices. These certifications not only guarantee product quality but also demonstrate environmental responsibility, which increasingly influences purchasing decisions in global markets. Buyers should verify that all certifications are current and conduct regular audits to ensure ongoing compliance.

Production Capacity and Infrastructure Assessment

Evaluating a supplier's production capacity requires thorough analysis of their processing facilities, equipment capabilities, and operational efficiency. Modern frozen seafood suppliers should operate state-of-the-art freezing systems that maintain optimal temperatures throughout the production cycle, ensuring product integrity and extending shelf life. Blast freezing capabilities, temperature-controlled storage areas, and automated packaging systems indicate advanced operational capabilities.

Infrastructure assessment should include examining the supplier's cold chain management systems, backup power systems, and quality control laboratories. Reliable suppliers invest in redundant systems to prevent temperature fluctuations during power outages or equipment failures. On-site quality control laboratories enable real-time testing for freshness, contamination, and nutritional content, ensuring that products meet specified standards before shipment.

Quality Control and Traceability Systems

Comprehensive Quality Assurance Programs

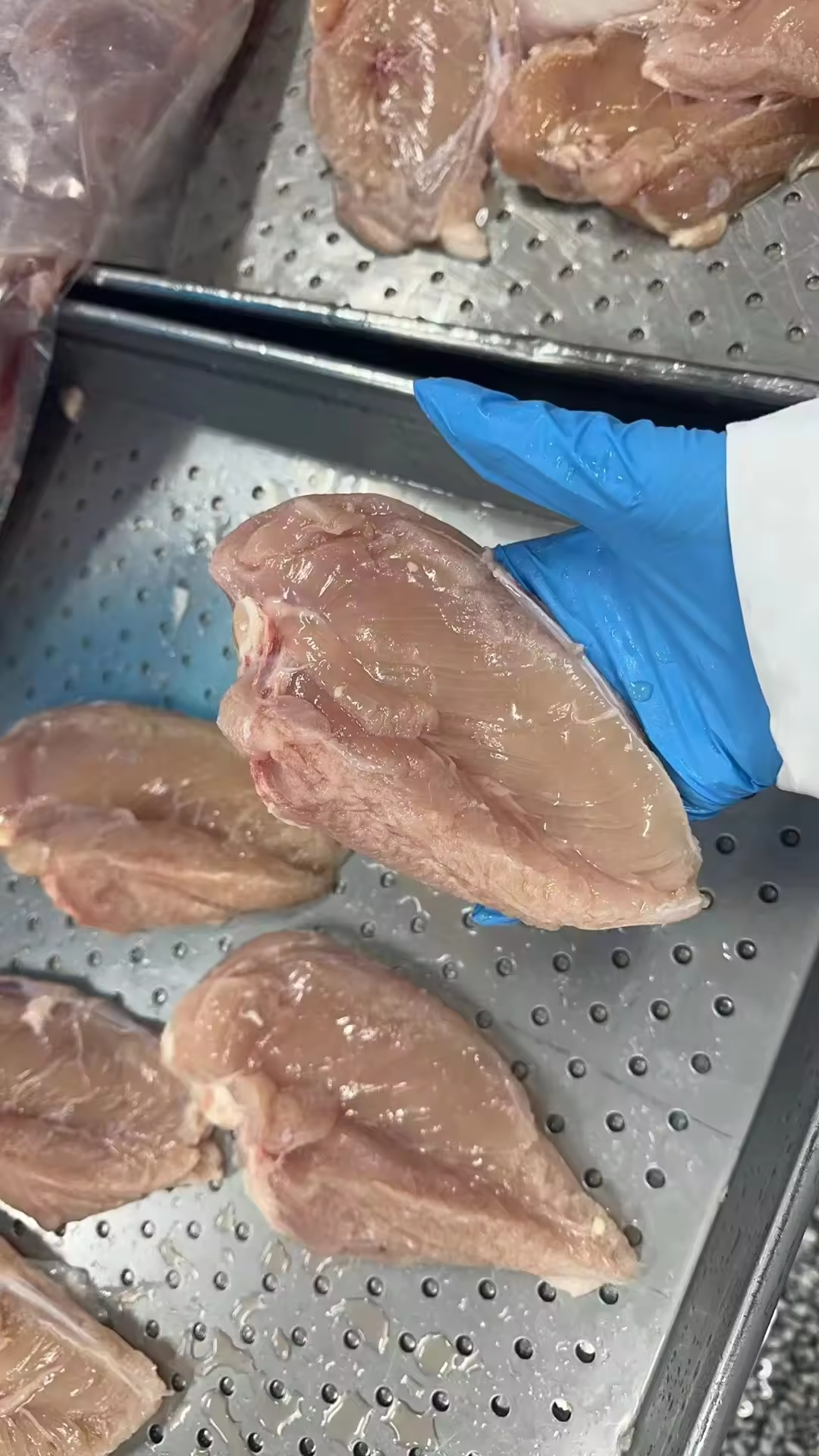

Effective quality control systems form the foundation of successful supplier relationships in the frozen seafood industry. Leading suppliers implement multi-stage quality control processes that begin with raw material inspection and continue through every production phase until final packaging. These programs should include microbiological testing, chemical analysis, sensory evaluation, and physical inspections to identify potential issues before products reach international markets.

Documentation systems play a crucial role in quality assurance, enabling suppliers to track production batches, identify contamination sources, and implement corrective actions when necessary. International buyers should require detailed quality certificates for each shipment, including test results for heavy metals, pathogens, and preservatives. Regular third-party audits provide independent verification of quality control systems and help maintain consistent standards across all production facilities.

Supply Chain Transparency and Traceability

Modern consumers and regulatory agencies demand complete traceability throughout the seafood supply chain, making this capability essential for international suppliers. Comprehensive traceability systems enable suppliers to track products from fishing vessels or aquaculture farms through processing, packaging, and distribution. This transparency helps prevent fraud, ensures sustainable sourcing practices, and enables rapid response to food safety incidents.

Digital traceability platforms provide real-time visibility into supply chain operations, allowing buyers to verify product origins, processing dates, and transportation conditions. Blockchain technology increasingly supports these systems, creating immutable records that enhance trust and accountability. Suppliers who invest in advanced traceability systems demonstrate their commitment to transparency and provide valuable risk management tools for international buyers.

Logistics and Distribution Capabilities

Cold Chain Management Excellence

Maintaining product quality during international transportation requires sophisticated cold chain management capabilities that extend from production facilities to final delivery destinations. Experienced frozen seafood suppliers understand the complexities of international shipping and implement comprehensive temperature monitoring systems throughout the distribution process. These systems should include real-time tracking devices, temperature data loggers, and automated alerts for any deviations from specified temperature ranges.

Effective cold chain management encompasses proper packaging materials, insulation systems, and refrigerated transportation options. Suppliers should offer various packaging configurations to meet different shipping requirements, from small retail portions to large bulk containers. Partnership relationships with specialized logistics providers ensure reliable temperature-controlled transportation across different climate zones and shipping routes.

Global Shipping and Documentation Expertise

International trade requires extensive documentation and regulatory compliance across multiple jurisdictions, making supplier expertise in these areas invaluable for smooth operations. Experienced suppliers maintain detailed knowledge of import regulations, health certificates, and customs requirements for different destination countries. This expertise helps prevent shipment delays, reduces compliance costs, and ensures products meet all regulatory requirements upon arrival.

Flexible shipping options accommodate various buyer requirements, from small sample orders to large commercial shipments. Suppliers should offer multiple transportation modes, including air freight for urgent deliveries and sea freight for cost-effective bulk shipments. Comprehensive insurance coverage protects against transportation risks, while experienced logistics coordination ensures timely delivery to international destinations.

Financial Stability and Business Relationships

Supplier Financial Assessment

Evaluating supplier financial stability protects international buyers from supply disruptions caused by business failures or cash flow problems. Financial assessment should include reviewing audited financial statements, credit ratings, and payment histories with other suppliers and service providers. Stable suppliers demonstrate consistent profitability, manageable debt levels, and adequate working capital to support ongoing operations and growth investments.

Long-term financial stability enables suppliers to invest in equipment upgrades, facility improvements, and technology enhancements that benefit their customers. Buyers should consider suppliers who reinvest profits into operational improvements rather than those operating on minimal margins with limited growth potential. Financial transparency and willingness to share relevant financial information indicate trustworthy business relationships.

Communication and Customer Service Standards

Effective communication forms the foundation of successful international supplier relationships, particularly when dealing with time zone differences, language barriers, and cultural considerations. Professional frozen seafood suppliers maintain dedicated customer service teams with multilingual capabilities and extensive product knowledge. These teams should provide responsive communication through multiple channels, including email, phone, video conferencing, and instant messaging platforms.

Customer service excellence extends beyond basic order processing to include technical support, product development assistance, and market intelligence sharing. Suppliers who understand their customers' business needs can provide valuable insights into market trends, regulatory changes, and product innovations. Regular communication schedules, progress updates, and proactive problem resolution demonstrate commitment to long-term partnership success.

FAQ

What certifications should I prioritize when selecting frozen seafood suppliers

Focus on suppliers with HACCP and ISO 22000 certifications for food safety management, plus industry-specific certifications like BAP or MSC for sustainable practices. BRC or SQF certifications indicate additional quality management capabilities. Verify all certifications are current and conduct regular compliance audits to ensure ongoing standards maintenance.

How can I verify the quality of products before establishing a supplier relationship

Request product samples with complete documentation including quality certificates, test results, and traceability records. Conduct independent laboratory testing for key parameters like freshness, contamination, and nutritional content. Visit supplier facilities when possible or arrange third-party audits to verify production capabilities and quality control systems firsthand.

What should I consider regarding minimum order quantities and pricing structures

Evaluate minimum order quantities against your storage capacity, cash flow requirements, and product turnover rates. Request detailed pricing structures including volume discounts, seasonal variations, and additional fees for special packaging or expedited shipping. Compare total landed costs rather than just unit prices to understand true value propositions.

How important is geographic location when choosing international suppliers

Geographic location significantly impacts shipping costs, transit times, and regulatory requirements. Consider suppliers in regions with established seafood industries, reliable infrastructure, and favorable trade relationships with your destination markets. Proximity to major shipping ports reduces transportation costs and enables more flexible delivery schedules for urgent orders.

Table of Contents

- Essential Criteria for Evaluating Supplier Qualifications

- Quality Control and Traceability Systems

- Logistics and Distribution Capabilities

- Financial Stability and Business Relationships

-

FAQ

- What certifications should I prioritize when selecting frozen seafood suppliers

- How can I verify the quality of products before establishing a supplier relationship

- What should I consider regarding minimum order quantities and pricing structures

- How important is geographic location when choosing international suppliers